What’s New at Aqua Metals

Aqua Metals Named ‘Top Project’ Winner by E+E Leader

Aqua Metals was announced as Top Project of the Year in the prestigious Environment+Energy Leader Awards program for 2024.

Aqua Metals Q4 Earnings & 2023 Highlights

Aqua Metals Q4 Earnings & 2023 Highlights

Global Recycling Day: Aqua Metals Recycling Impact

Explore articles and multimedia covering Aqua Metals’ journey to revolutionizing the lithium battery recycling industry.

Aqua Metals: Creating a Safe, Sustainable Energy Future

Aqua Metals is the only company that has produced a commercially proven sustainable, closed-loop metal recycling process that is capable of producing the world’s purest metals.

Our Innovation Center is developing the cleanest metals recycling technologies that are better for the environment, economically competitive and safe for workers.

Lithium Ion: Powering the New Energy Era

Aqua Metals is applying its commercialized clean, water-based recycling technology principles to develop the cleanest and most cost-efficient recycling solution for lithium-ion batteries.

Our process will produce higher quality products at a lower operating cost without the damaging effects of furnaces and greenhouse emissions.

PRESS RELEASES

Aqua Metals, Inc. (AQMS) News

Aqua Metals, Inc. (AQMS) News

- Aqua Metals Announces 2024 Annual Meeting of Stockholders April 1, 2024

- Aqua Metals Announces Participation in Upcoming Investor Conferences March 28, 2024

- Aqua Metals Advances Sierra-ARC Lithium Battery Recycling Campus and Secures Offtake Partnership; Reports Full-Year 2023 Financial Results March 27, 2024

- Aqua Metals and 6K Energy Sign Strategic Supply Agreement to Establish North America’s First Sustainable Lithium Battery Supply Chain March 26, 2024

IN THE NEWS

Aqua Metals is building a more sustainable battery recycling ecosystem

David Regan sits down with Charged to discuss building a circular supply chain for lithium batteries.

Aqua Metals Inks Supply Agreement With 6K Energy

RECYCLING TODAY – Reno, Nevada-based lithium-ion battery (LIB) recycler Aqua Metals and North Andover, Massachusetts-based LIB materials producer 6K Energy have signed a strategic supply

Aqua Metals, Dragonfly, NBC, Discuss NV Lithium Economy

Nevada Newsmakers- Aqua Metals’ Matt Roberts joins Nevada Newsmakers Caleb Cage, Denis Phares, and the Nevada Battery Coalition to discuss the lithium economy in Nevada, and

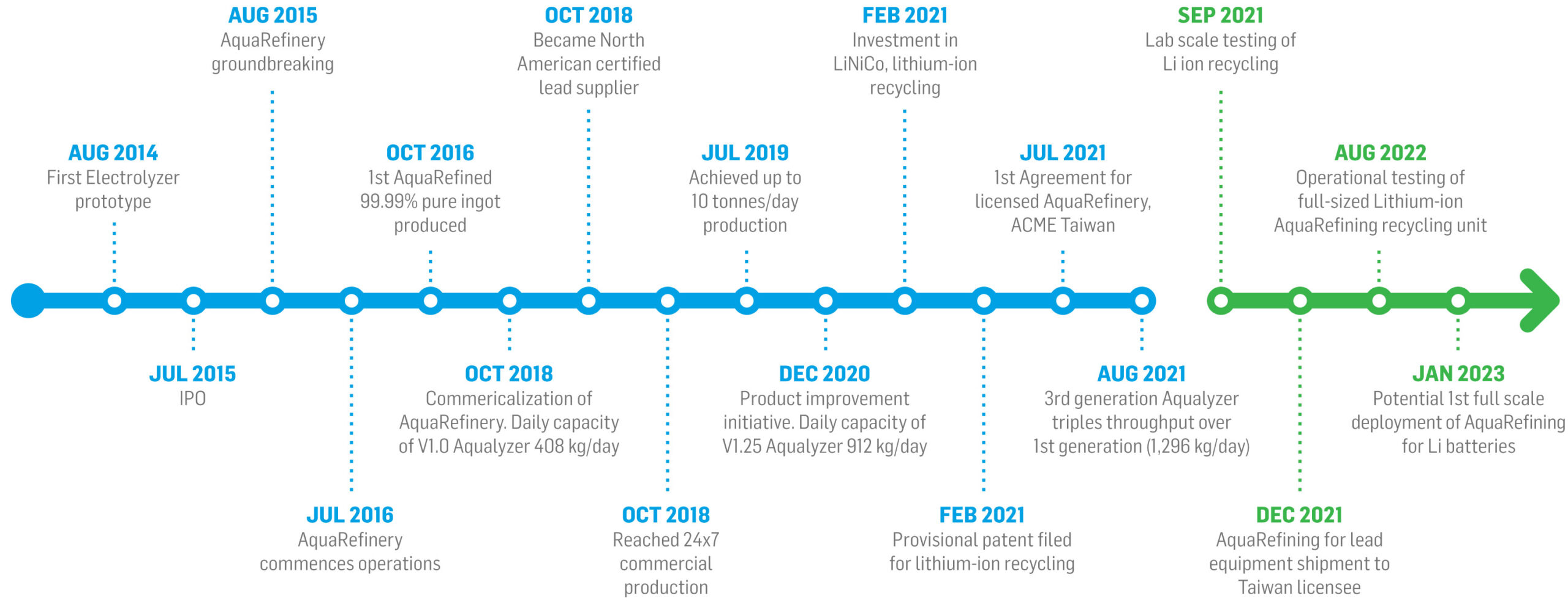

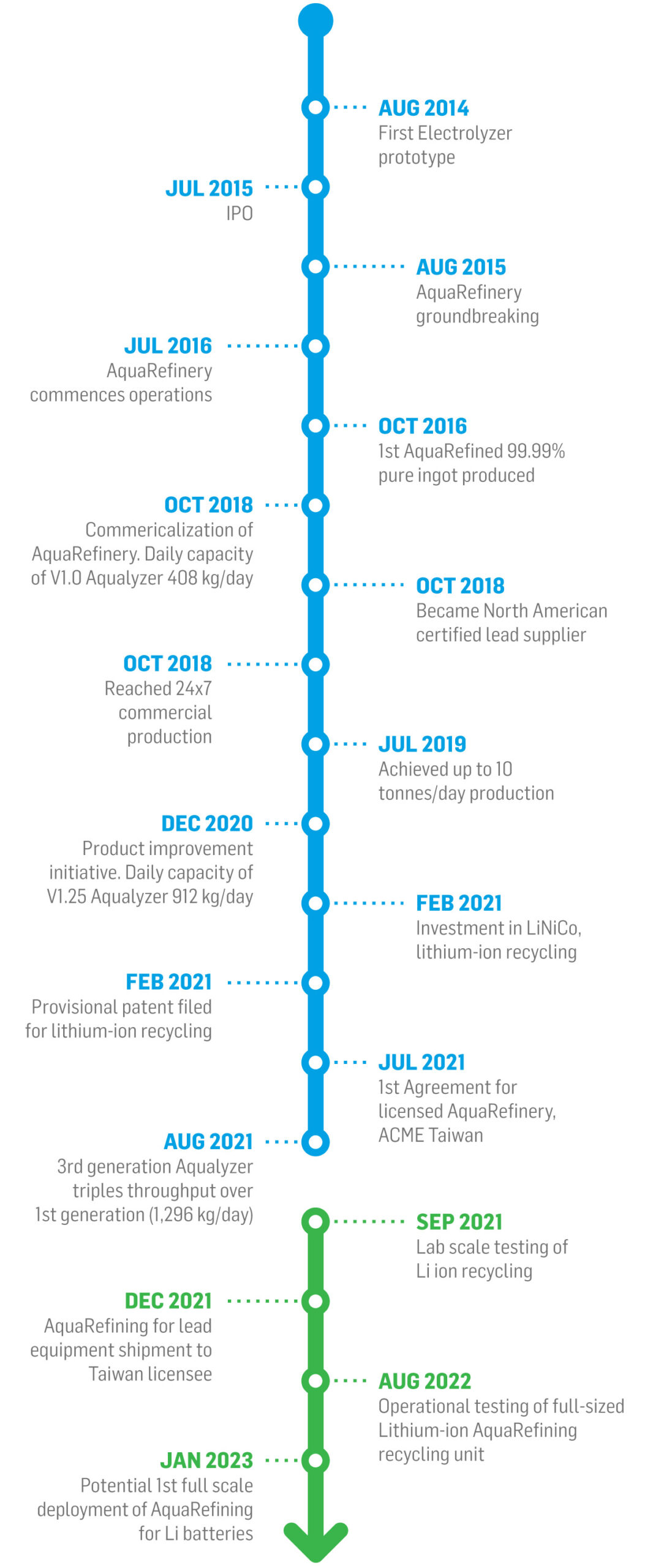

Proven Technology with Lead Recycling

Aqua Metals’ patented and commercially proven AquaRefining technology is a cleaner and more cost-efficient lead recovery and recycling process.

This room-temperature, closed loop, water-based process is fundamentally nonpolluting, cost-efficient and produces the purest lead ever made from a recycling technique. The first licensed AquaRefinery is being established in Taiwan, one of the fastest growing lead-recycling regions.

AQUAMETALS MILESTONES

Aqua Metals is building a more sustainable battery recycling ecosystem

David Regan sits down with Charged to discuss building a circular supply chain for lithium batteries.

Aqua Metals Inks Supply Agreement With 6K Energy

RECYCLING TODAY – Reno, Nevada-based lithium-ion battery (LIB) recycler Aqua Metals and North Andover, Massachusetts-based LIB materials producer 6K Energy have signed a strategic supply agreement in the effort to establish a sustainable circular supply chain in North America for the critical minerals needed for manufacturing LIBs.

Aqua Metals, Dragonfly, NBC, Discuss NV Lithium Economy

Nevada Newsmakers- Aqua Metals’ Matt Roberts joins Nevada Newsmakers Caleb Cage, Denis Phares, and the Nevada Battery Coalition to discuss the lithium economy in Nevada, and the growing supply chain for recycling technology.

Interview With Aqua Metals, a Company Leading the Green Economy and NV Job Development

Live Work Play- For companies and individuals contemplating a move to the Reno-Sparks area, Aqua Metals advises embracing the opportunity wholeheartedly. The region is rapidly becoming a hub for innovative industries, particularly in green technology and advanced manufacturing. In a recent interview, Aqua Metals shared their position in the market, their goals for the future, and why you should consider moving to Reno, NV.

Aqua Metals, Inc. (AQMS) News

Aqua Metals, Inc. (AQMS) News

- Aqua Metals Announces 2024 Annual Meeting of Stockholders April 1, 2024

- Aqua Metals Announces Participation in Upcoming Investor Conferences March 28, 2024

- Aqua Metals Advances Sierra-ARC Lithium Battery Recycling Campus and Secures Offtake Partnership; Reports Full-Year 2023 Financial Results March 27, 2024

- Aqua Metals and 6K Energy Sign Strategic Supply Agreement to Establish North America’s First Sustainable Lithium Battery Supply Chain March 26, 2024