What’s New at Aqua Metals

DeepDive Episode 5: Expanded Recycling Vision

The latest episode of the AQMS DeepDive Podcast on upcoming plans for lithium battery recycling.

Closing the Year with Major Progress in Sustainable Battery Recycling

As 2024 comes to a close, Aqua Metals is proud to share our recent achievements in advancing the future of sustainable lithium battery recycling.

Tackling the Sodium Sulfate Challenge in Lithium Battery Recycling: A Core Advantage of Aqua Metals’ Technology

We take a look at soduim sulfate, one of the environemtal challenges that comes along with a growing EV industry.

Aqua Metals: Creating a Safe, Sustainable Energy Future

Aqua Metals is the only company that has produced a commercially proven sustainable, closed-loop metal recycling process that is capable of producing the world’s purest metals.

Our Innovation Center is developing the cleanest metals recycling technologies that are better for the environment, economically competitive and safe for workers.

Lithium Ion: Powering the New Energy Era

Aqua Metals is applying its commercialized clean, water-based recycling technology principles to develop the cleanest and most cost-efficient recycling solution for lithium-ion batteries.

Our process will produce higher quality products at a lower operating cost without the damaging effects of furnaces and greenhouse emissions.

PRESS RELEASES

Aqua Metals, Inc. (AQMS) News

Aqua Metals, Inc. (AQMS) News

- Aqua Metals Announces 2025 Annual Meeting of Stockholders June 18, 2025

- Aqua Metals Announces Allowance of Foundational U.S. Patent for Lithium Battery Recycling Technology June 2, 2025

- Aqua Metals Expands Product Platform with Advancements in Nickel, MHP, and LFP Recycling; Reports First Quarter 2025 Results May 8, 2025

- Aqua Metals Announces CFO Transition and Appointment of Eric West May 7, 2025

IN THE NEWS

Aqua Metals Initiates $33M Loan Agreement To Fund Commercial-Scale Lithium Battery Recycling Plant

BENZINGA – In a press release on May 15, Aqua Metals signed a non-binding term sheet with “one of the world’s largest privately held companies.”

The Hidden Economic And Environmental Cost Of EV Batteries And How To Create A Sustainable Circular Economy

BENZINGA – Benzinga’s new article covers the hidden costs fo EV recycling and how Aqua Metals plans to build a sustainable circular supply chain.

Is EV Battery Recycling Ready For Prime Time?

EV PULSE – From smartphones to EVs to backup power, lithium-ion batteries run much of our modern world. But we’ve got a big problem on

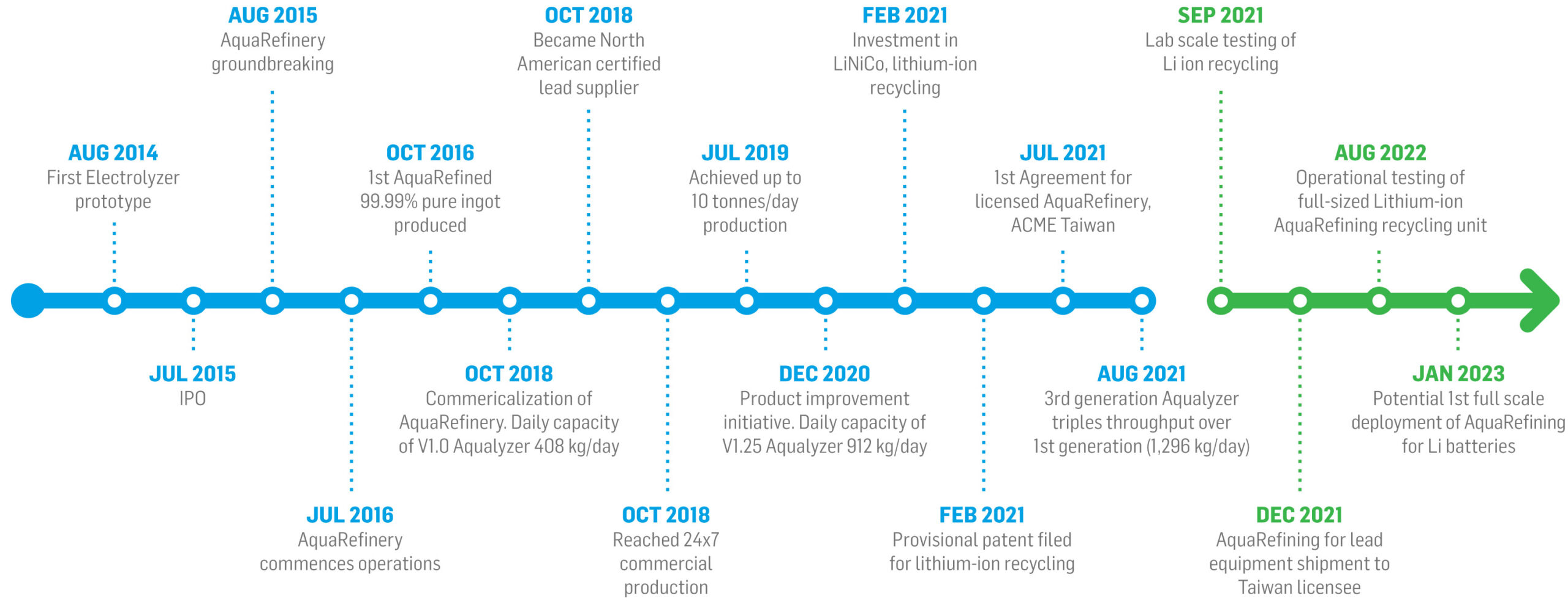

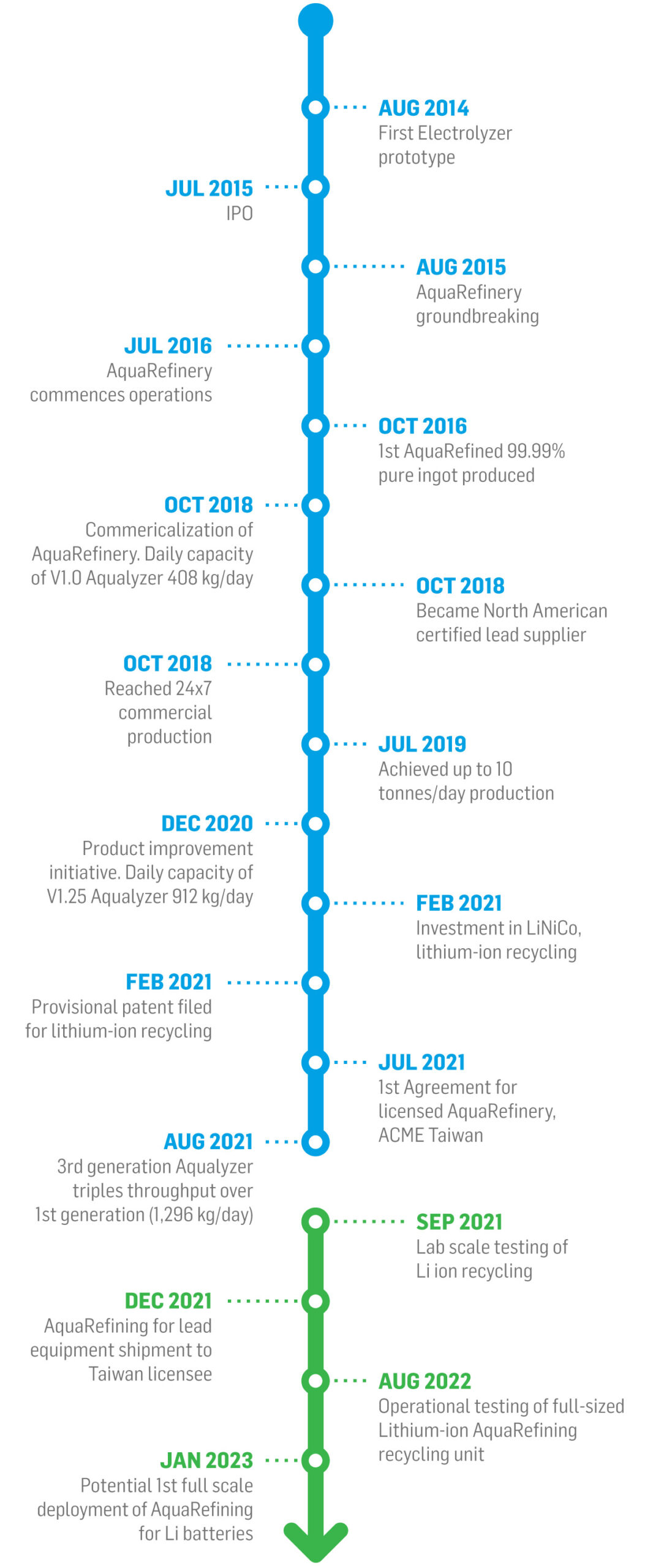

Proven Technology with Lead Recycling

Aqua Metals’ patented and commercially proven AquaRefining technology is a cleaner and more cost-efficient lead recovery and recycling process.

This room-temperature, closed loop, water-based process is fundamentally nonpolluting, cost-efficient and produces the purest lead ever made from a recycling technique. The first licensed AquaRefinery is being established in Taiwan, one of the fastest growing lead-recycling regions.

AQUAMETALS MILESTONES

Aqua Metals Initiates $33M Loan Agreement To Fund Commercial-Scale Lithium Battery Recycling Plant

BENZINGA – In a press release on May 15, Aqua Metals signed a non-binding term sheet with “one of the world’s largest privately held companies.” The $33 million credit facility would complete phase one of the company’s Sierra AquaRefining Campus (ARC).

The Hidden Economic And Environmental Cost Of EV Batteries And How To Create A Sustainable Circular Economy

BENZINGA – Benzinga’s new article covers the hidden costs fo EV recycling and how Aqua Metals plans to build a sustainable circular supply chain.

Is EV Battery Recycling Ready For Prime Time?

EV PULSE – From smartphones to EVs to backup power, lithium-ion batteries run much of our modern world. But we’ve got a big problem on our hands when these energy reservoirs wear out, especially in a future where electric vehicles are the norm. Today we’re talking to experts to explore the current state of electric car battery recycling. We’ll learn how it’s done and why it’s so important, and we’ll learn all recycling isn’t necessarily good for the environment.

Aqua Metals joins $4.99M DOE grant project

RECYCLING TODAY – Aqua Metals Inc., a Reno, Nevada-based lithium-ion battery (LIB) recycler will collaborate in a $4.99 million U.S. Department of Energy (DOE) grant project as part of a consortium led by Penn State University. The initiative is aimed at establishing a fully domestic supply chain for critical minerals used in a range of modern technologies, including electric vehicles (EVs) and renewable energy systems.

Aqua Metals, Inc. (AQMS) News

Aqua Metals, Inc. (AQMS) News

- Aqua Metals Announces 2025 Annual Meeting of Stockholders June 18, 2025

- Aqua Metals Announces Allowance of Foundational U.S. Patent for Lithium Battery Recycling Technology June 2, 2025

- Aqua Metals Expands Product Platform with Advancements in Nickel, MHP, and LFP Recycling; Reports First Quarter 2025 Results May 8, 2025

- Aqua Metals Announces CFO Transition and Appointment of Eric West May 7, 2025