PILOT RECYCLING HUB

In the fall of 2022, Aqua Metals began commissioning the first sustainable lithium-ion battery recycling facility, located at the company’s Innovation Center, in the heart of Nevada’s ‘Lithium Loop.’

Summer of 2023, we moved to 24×5 and our Pilot is fully operational.

Aqua Metals has completed the commissioning of our first-of-its-kind Li AquaRefining Pilot! The company is now operating our sustainable battery recycling facility 24-hours-a-day, five days a week and recovering saleable quantities of the full suite of valuable metals and minerals contained in spent lithium batteries.

Aqua Metals is producing lithium hydroxide, nickel, cobalt, copper, and manganese dioxide, and is scaling production at the pilot facility to 75 tons per year of battery materials recycled.

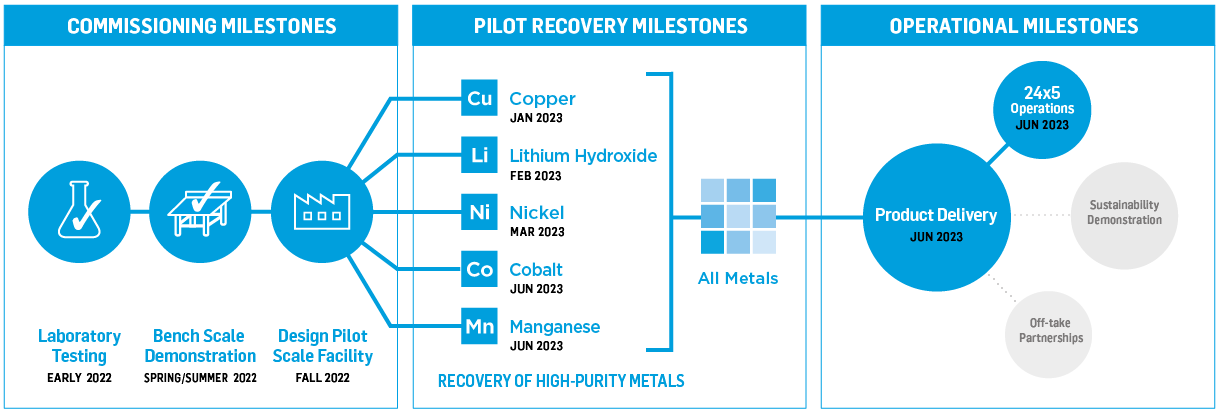

Having previously demonstrated the patent-pending Li AquaRefining™ technology at lab and bench scale, in December of 2022 the company initiated operations in a dedicated pilot recycling facility. Aqua Metals sustainable recycling technology replaces fossil fuels and chemicals with electricity, creating a low-carbon, circular supply of critical battery metals with a fraction of the waste.

The Li AquaRefining Pilot is a closed-loop, low-temperature recycling system able to reclaim all the critical minerals in ‘black mass’—a ground up mixture of the metals in lithium batteries. Aqua Metals powers this efficient process using electricity (instead of polluting furnaces or intensive chemical processes) dramatically reducing the emissions and hazardous waste typical of battery recycling.

Aqua Metals Pilot Recycling Facility Timeline

We will continue to provide updates, photos, and videos as we ramp up operations at our pilot facility, achieve new milestones, and commence delivery of our clean recycled metals back into the domestic lithium-ion battery supply chain.

Latest Blog Posts: Pilot Facility

Global Connections: Dutch Delegation Visit

Pilot Complete: Aqua Metals is Ready to Liftoff

Senator Cortez Masto Highlights Aqua Metals’ Sustainable Battery Recycling on Floor of NV Legislature

Senator Catherine Cortez Masto Visits Aqua Metals, Lauds Sustainable Lithium Battery Recycling Technology

Nickel: Unsung Hero of Clean Energy Supply Chains

AQMS Pilot Video Update: Drone Tour

Pilot Facility Photo Gallery

AQUA METALS SOLVES THE MASSIVE LITHIUM-ION RECYCLING CHALLENGE

How our approach is different from other recycling solutions:

NO SMELTING

No furnace required, no greenhouse emissions

HIGHER %

Recovers a higher percentage

of metals in a higher

quality form

MINIMAL WASTE

Closed-loop process that

recycles chemicals

and water

HIGHER QUALITY

Produces higher quality

products at a lower

operating cost